about us プロジェクト概要

a

300年前から磨かれた丹後ちりめんの技巧とパリで磨かれた

クリエイションの邂逅は何を生み出すか。

What happens when you bring together the finesse of Tango Chrimen (locally made silk crêpe which has been perfected for over 300 years) and the fine creations of Paris?

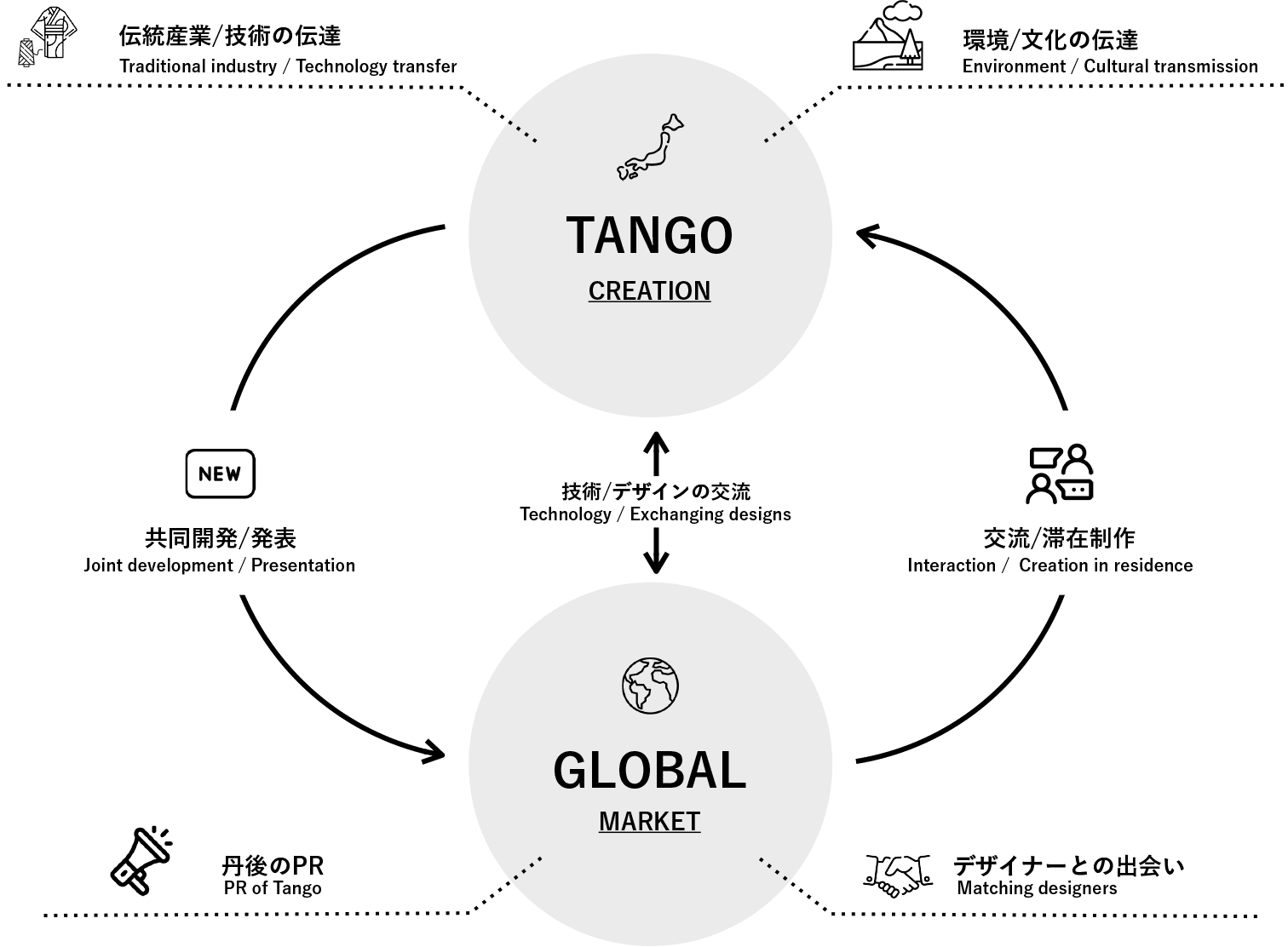

2019年よりスタートした「TANGO CREATION PLATFORM」は、丹後が持つ様々な魅力を外に開くことで新たな地域の可能性を模索するプロジェクト。「丹後ちりめん」と世界で活躍するクリエイター/デザイナーが滞在と交流を通じ、新たな領域の丹後ちりめんを模索する。滞在の中で出会う丹後の伝統、文化、風土、そしてリアルな工房の現場から様々なインスピレーションを得て作品が創造される。2020年は、COVID-19の影響により実行困難な状況におかれたが、オンライン観光やビデオ会議を通じて本来の滞在体験に近づけるかたちを工夫し開催。今回の特殊な環境下でも、関係者の相互協力と熱意により国を超えたクリエイションが可能なことを証明した。日本と海外を拠点にするデザイナーの感性が融合した、新たな[丹後ちりめん]の可能性を紹介する。

TANGO CREATION PLATFORM started in 2019. It’s a type of ‘artist-in-residence’ project to cultivate new potential in Tango by opening our doors more widely to the world. Creators and designers are invited to develop and evolve new types and uses for renowned Tango Chirimen through communication and residential programs. Our aim is to foster artistic space for creators, both from around Japan and internationally, to stay in Tango and develop their work. Gaining inspiration from the meeting of tradition and culture, coupled with the real atmosphere of local ateliers and artists, this will be a unique and exciting experience.In 2020, we had a difficult time due to COVID-19, but we continued working hard by holding online meetings and online touring, so that participants could experience the real Tango.And we proved that it is possible to create exciting new work through the enthusiastic cooperation of creators.Please see one new stage of “Tango Chirimen,” which was created this year by the collaboration of Japanese and French artists.

丹後ちりめんとは

1300年以上前から絹織物が綿々と織り続けられてきた丹後地方では300年前に大きな革新がもたらされた。

それは、丹後ちりめんの誕生である。

Tango Province of northern Kyoto Prefecture, which has a history of over 1,300 years of woven silk textile, experienced the innovation about 300 years ago; the birth of Tango Chirimen, also known as silk crepe.

江戶時代に峰山の絹屋佐平治と、加悦谷の手米屋小右衛門、山本屋佐兵衛、木綿屋六右衛門が京都西陣から技術を習得し丹後に広めた。

In Edo period, Saheiji Kinuya (from Mineyama area), Koemon Tegomeya, Sahei Yamamotoya and Rokuemon Momenya (from kayadani area) learned the technique in Nishijin area in Kyoto and brought it back to Tango.

ちりめんは、緯糸に強い撚りをかけた生糸を使い、生地に細かい凸凹状の「シボ」がある織物。しなやかな風合いで、発色性に富むのが特徴。

Chirimen is a form of textile with a pattern of fine, bumpy-textured grains, caused by the weft twisted about 3000 times per meter. It is well known for its soft texture and the dyed colors come out vividly.

正装には欠かせないラグジュアリーな生地として日本のきもの文化を支え続けている。

そのような歴史風土のなかで、現在、ちりめん以外にも多くの新たな織物がこの丹後の地で育っている。

そしていま、世界のクリエータとの新たな交流により、世界に向け、さまざまなオリジナルの織物が生まれ出した。

ちりめん誕生から300年を経て次代への革新が進む。

Historically and even today, it continues to be used as luxurious and formal kimono textile in Japan.

And now, through the collaborations with international creators, a lot of unique textiles besides Chirimen are being produced in the region. 300 years after the birth of Chirimen, Tango moves on to next generation of innovations.

partners 事業者紹介

株式会社一色テキスタイル Isshiki textile co.,ltd

一色テキスタイルは、シルクから化合繊まで糸の特性を活かしながら、日常使いのできるちりめん製品の製造を行う織物メーカーです。また建築物の内装に用いるインテリアとしての、ちりめんの新たな可能性も切り開いています。

Isshiki Textile is a textile manufacturer that produces crepe silk items for everyday use, while effectively utilizing the properties of various types of yarn from silk to synthetic fibers. It also opens up new possibilities for crepe as a material for building interiors.

臼井織物株式会社 Usui Orimono Co.,Ltd.

⾅井織物は数少ない全製品の撚⽷と製織を⾃社で⾏う合繊丹後ちりめん織元として、1952 年の創業以来3,000 種類を超えるちりめん⽣地の開発で蓄積した技術と経験を活かし、強撚⽷を⽤いた三次元の奥⾏きと深みのある丹後ちりめんを織り続けています。

Since 1952, Usui Orimono Co., Ltd. has been weaving Tango chirimen with synthetics such as polyester and rayon, as well as hybrids of natural and synthetic yarns twisted in-house. With experience and skills acquired through developing more than 3,000 different chirimen, they are able to depict rich texture & depth, giving a three-dimensional appearance to the textile.

江原産業株式会社 create ebara

着物の織り柄の型である「紋紙」をつくる会社から始まり、その着物の紋⼯の技術を活かしたシルクジャカードを作るのに⻑けた会社です。市松グラデーションやダブルフェイスなど、独⾃の技術やデザインで、和と洋やクラッシックとモダンを融合したテキスタイルをデザインから製織まで⼀貫して創り出しています。

Beginning as a company that make “mongami”, the patterns for weaving Kimono textiles, they are expert at producing silk jacquard using their traditional technology, creating textiles that for example feature checkered gradations or are double faced. From design to weaving, they produce textiles in which Japanese and Western, or classic and modern, are fused.

山象舎 Sanzosya

自然豊かな丹後での生活の中で、日々触れ合う植物を作品に昇華させます。図案化した植物の色素でちりめんを染め上げた作品、採集した植物の繊維を織り込んだ作品など、自然から得たイマジネーションと素材により制作がなされています。

Tango is a place of abundant nature, and plants that people come into contact with each day are incorporated into the works of Sanzosha. These derive both inspiration and materials from nature and materials, including in works made with crepe silk dyed with plant pigment designs and textiles made from plants gathered in the wild.

柴田織物 Shibata Textile.

京都府北部に位置する丹後半島は約1300 年の歴史を紡ぐ絹織物の⾥。今⽇に⾄るまで、丹後ちりめんに代表される多彩な織物が⽣産されています。

柴⽥織物は明治19 年に⼿機で創業しました。やがて動⼒織機による丹後ちりめんの製造を開始、昭和61 年には最⾼級の織物とされる縫取ちりめんによる留袖や訪問着の製造を始めます。五代⽬ 柴⽥祐史は縫取ちりめんの技法と現代的な感覚を掛け合わせた製品づくりに着⼿し、デザイナーのコレクション⽣地、映画の⾐装など幅広い分野へ可能性を広げてきました。お客様のイメージやアイデアからスケッチを描き、織物のデータへと変換し、絹⽷の⾊を合わせてシャットル織機で織る。柴⽥織物は全て⾃社において⼀貫したものづくりをしております。⼀反のオーダーから、お客様の想いを織物にしてご提案いたします。

Tango peninsula, located in the northern part of Kyoto prefecture, is an area of silk fabric production, with around 1300 years of history. Various textiles, such as Tango Chirimen, are still being produced today. Shibata Textile was founded in 1886 as a hand weaving company and eventually started manufacturing Tango chirimen using electric-powered looms. They later moved to producing the highest class of kimono textile for celebrations such as tomesode or homongi, using the finest woven technique of “*Nuitori chirimen”. Yuji Shibata, their fifth generation owner, has expanded the possibilities to a wide range of new uses and materials. Using classic technology fused with a modernist sensibility, his work features in designer collections and even in costumes for a Hollywood feature film. He draws sketches from the client’s image, converts these into data, matches the colours of the silk and weaves them on shuttle type looms. Shibata Textile produces the textile from scratch. From the very outset, they weave the product with the client’s aspirations fully in mind.

*Nuitori chirimen: decorative thread of gold, silver, urushi lacquer or lame is woven in ornamental patterns on chirimen fabric for ceremonial kimonos. It gives the appearance of intricately gorgeous embroidery, even though actually woven.

染色工房嶋津 Dyeing workshop Shimazu

ローケツ染、絞り染、刷毛染、草木染、糸目友禅染などの染色技法を駆使し一点物の製品を制作する工房です。

染には化学染料をはじめ丹後の山野に自生する植物などを用いており、商品の使い手と色との出会いはまさに一期一会です。

Senshoku Kobo is a workshop that produces one-of-a-kind silk textiles using dyeing techniques such as wax-resist dyeing, tie-dyeing, brush dyeing, plant juice dyeing and thread-line yuzen dyeing. Plants growing naturally in the mountain area of Tango are used, and encounters between the user and the colors of products are truly once-in-a-lifetime opportunities.

創作工房糸あそび Creative Workshop ITOASOBI

工房独自の織り技術と、丹後独特の織り・撚糸の技術を背景とし、シルクリボンをはじめとする様々な糸種と織り方を組み合わせ、「丹後であって丹後らしくない生地の創造と企画」を心がけて、独自の生地を織り上げます。

Based on the studio’s unique weaving techniques and the Tango region’s distinctive techniques of weaving and yarn twisting, Itoasobi combines various yarn types such as silk ribbons and various weaving methods, aiming to produce their own distinctive “ideas and plans for textiles that are Tango products, yet differ from the typical Tango look.”

大善株式会社 Daizen Co., Ltd.

シルクなどの天然繊維と化学繊維は使⽤する染料の種類が異なります。⼤善株式会社は2種類の染料を使い分け、丹後の歴史ある⽣地に適したプリントをしていくよう⼼がけています。

Natural fibers such as silk, and synthetic fibers, use different categories of dyes. Daizen Co., Ltd. creates dyes that are suitable for printing the long established fabrics of Tango.

民谷螺鈿株式会社 TAMIYA RADEN Ltd.

貝を織り込んだ螺鈿織をはじめ、漆、木、革など様々な素材を緯糸とし、革新的な織物を制作しています。織物の伝統技法と、丹後の豊かな自然のインスピレーションを大切に、常に新たな表現に挑戦し続けています。

Tamiya produces innovative textiles including “raden-ori” with seashells woven in, and woven fabrics with weft made of diverse materials such as lacquer, wood and leather. The studio cherishes traditional textile techniques and inspiration derived from the rich natural environment of Tango, and constantly takes on the challenge of new forms of expression.

田勇機業株式会社 TAYUH TEXTILE INDUSTRY CORP.,

撚糸から機織り、染めまでを手掛け、丹後ちりめんを製造する織元です。水を用いて緯糸に強い撚りをかける「八丁撚糸」の技術により、丹後ちりめんの特徴である、繊細で美しいシボのある生地を作り出します。

This weaving studio carries out all stages of Tango chirimen crepe silk from yarn twisting to weaving and dyeing. Hatcho-Nenshi yarn twisting, in which water is used to twist the weft strongly, produces fabrics with the fine, beautiful grain characteristic of Tango chirimen crepe silk.

丹後織物工業組合 Tango Textile Industrial Association

丹後産地で生産されたシルクを中心とする織物に、組合直営の加工場において永年にわたり培われた技術と各種設備により、ニーズに対応した精練・染色・仕上げ加工と合わせ、高品質の製品を市場に送り出すために厳しい検査を実施し、産地ブランドマークの信頼を支えています。また、製品の多様化、高品質化に対応するため、商品開発のための各種加工技術試験・研究開発を行っています。

We support the refining, dyeing and finishing processes of predominantly silk fabric at our Tango factory, using long established technologies in high quality facilities. We carry out strict inspections before sending goods to market, ensuring trust in the brand name of Tango merchandise. In order to respond to demands of diversification and quality, we conduct various processing technology tests as well as research and development for Tango products.

宮眞株式会社 MIYASHIN Co.,Ltd.

着物の小物用生地の織りから出発した宮眞は、現在ほかにない生地の開発に主眼を置きながら、服地と和装小物の生地を織っています。絹にとどまらず、合成繊維、さらに複合素材など、常に新しい素材を探し求め、取り入れています。

Miyashin was originally a producer of woven fabrics for kimono accessories, and today is primarily focused on development of unique fabrics used for clothing textiles and kimono accessories. In addition to using silk, they are consistently searching for and incorporating new materials, such as synthetic fibers and composite materials.

安田織物株式会社 Yasuda Textile Co., Ltd.

複雑な「からみ織」という技法で、繊細で透け感のある生地を表現します。丹後ちりめんの中でも、夏物と呼ばれる 「絽」 や「紗」を織り、近年はシルク素材を中心としたファッション・インテリア用生地の開発や、ストールなどファッション雑貨の製造販売も手がけています。

Yasuda Textile weaves delicate, transparent fabrics using the complex karami-ori (entwined weave) technique. Among the types of Tango chirimen silk crepe, they particularly produce “ro” silk gauze and “sha” (silk gauze more transparent than ro), known as summer textiles. In recent years they have been developing textiles for fashion and interiors, primarily using silk, and manufacturing and selling miscellaneous fashion items such as stoles.

株式会社山藤 YAMATOU CO.,LTD

創業以来約186年にわたり丹後ちりめんを織り続けています。シボの風合いが特徴的な正絹無地風呂敷や友禅風呂敷を中心に、風呂敷、袱紗、ストール、マフラー等、幅広いちりめん商品を製造、企画、販売しています。

Since its establishment approximately 186 years ago, Yamatou has been weaving Tango chirimen crepe silk. They produce, plan, and market a wide range of chirimen products such as furoshiki (traditional wrapping cloths), silk crepe wrappers, stoles, and scarves, with a focus on pure unpatterned silk and yuzen-dyed furoshiki.

遊絲舎 YUSHISHA

丹後で古くから受け継がれてきた藤織りの技術を用い、唯一無二の藤布を制作しています。藤は強く美しい素材であり、量産のできない希少な藤布だからこそ、長く大切に使われるようなものづくりを心がけています。

Using wisteria weaving techniques handed down for many generations in Tango, Yushisha creates unique wisteria textiles called “fujifu.” Wisteria is a sturdy and beautiful material, and because wisteria fabric is rare and cannot be mass-produced, they strive to produce fabric that will be treasured and used for many years.

PARANOMAD

経糸と緯糸の交差を空間的に捉え、「織物は彫刻」をコンセプトにテキスタイルを制作しています。空間を彩り、暮らしに長く寄り添う存在になることを願って、カーテンやスローケットなどを織り上げています。

Paranomad is a studio that interprets the intersection of warp and weft spatially, and produces fabrics based on the concept of “textiles as sculpture.” Items such as curtains and throw blankets are woven with the hope of adding color to interior spaces and becoming a lasting and well-loved part of everyday life.